How We Produce Firewood Logs

The process of our firewood log production from tree lengths to finished product, involves over quarter of a million pounds worth of equipment, a lot of hard work and a lot of patience.

The woodlands in Champleurie Estate, Linlithgow consist mainly of ancient and veteran trees and are classified as Ancient Woodlands, which carries a higher level of protection than normal (TPO) tree protection orders. The only time we use trees from the estate for firewood is when they are in diseased or storm damaged and require to be felled.

Our supply of firewood timber therefore consists of material from FSC managed forests which, like any crop, were planted solely for the purpose of harvesting and we use the upper part of the tree which is unsuitable for milling and regarded as waste.

Firstly the trees are cut into 2 to 3 metre sections and left out in all weathers in wood stacks for at least 2 years or until they reach about 30% moisture content (down from around 60% when first cut). We then split the larger diameter trees, with an attachment on our 8.6 ton excavator called a cracker, into sections that will go through our 17" diameter log processor. These logs then go into a large polytunnel to finish the seasoning/drying process using only the wind and sun that Mother Nature provides. This saves on the pollution from large amounts of good timber being burned to operate a kiln in kiln-drying of logs.

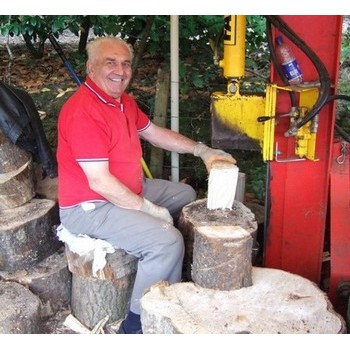

This material is then placed onto a hydraulic table which then feeds onto a conveyor that stops electronically in the exact position for the large harvester chain saw to cut into sections between 8" and 10" long. They in turn drop down into a chamber and a 15 ton hydraulic ram pushes them through an 8-way axe to produce the final logs.

These logs then travel up a conveyor and into a cleaning drum which seperates the good logs from the waste material. They then fall out of the drum into log IBC cages for the final storage and drying stage in our new polytunnel dryng areas.